Materials

In the rapidly evolving world of 3D printing and additive manufacturing, exciting innovations are constantly emerging in the realm of materials. From advancements in metal printing to innovations in bioprinting, these developments are revolutionizing the possibilities of what can be created.

Introduction to New Materials

With each passing day, new materials are being developed and adapted for 3D printing. This opens up a whole new world of opportunities for creators and manufacturers alike. From more traditional materials such as plastics and resins, to cutting-edge materials like graphene and carbon nanotubes, the range of options continues to expand. These new materials often boast enhanced properties like increased strength, flexibility, and durability, allowing for the production of more complex and functional designs.

Advancements in Metal Printing

One major breakthrough in recent years has been the advancement of metal printing technologies. With the ability to create intricate metal objects, the applications for industries such as aerospace, automotive, and healthcare are immense. Furthermore, the use of specialized metal alloys has led to the production of components with superior mechanical properties, pushing the boundaries of what was previously possible.

Innovations in Bioprinting

Bioprinting, a fascinating field that combines 3D printing with biology, has made great strides in recent years. This technology allows for the creation of functional human tissues and organs, paving the way for potential breakthroughs in regenerative medicine and drug testing. Scientists are now able to bioprint tissues with a high level of accuracy, mimicking the complexity and functionality of natural organs.

Use of Composites in 3D Printing

The use of composites in 3D printing has opened up new possibilities for lightweight and strong structures. By combining different materials, such as carbon fibers or glass fibers, with polymers, designers can create objects with exceptional strength-to-weight ratios. Composites are widely used in industries such as aerospace and automotive, where lightweight yet durable components are crucial.

Exploration of New Material Properties

Researchers and engineers are continually exploring the development of new material properties in 3D printing. This includes materials with self-healing capabilities, shape-shifting properties, and even conductive properties for the production of functional electronics. These developments have the potential to revolutionize industries ranging from electronics to healthcare.

The world of 3D printing and additive manufacturing is constantly evolving, particularly in the realm of materials. From advancements in metal printing to the fascinating field of bioprinting, these innovations are fostering new opportunities and pushing the boundaries of what is possible. As researchers continue to explore and develop new material properties, the potential for even further advancements is limitless.

This image is property of idtxs3.imgix.net.

## Hardware

Introduction to new 3D printers

Are you ready to dive into the world of 3D printing and additive manufacturing? Exciting innovations are constantly emerging in the field of hardware, making it easier than ever to bring your ideas to life. With the introduction of new 3D printers, you have a whole new realm of possibilities at your fingertips.

Breakthroughs in speed and accuracy

Gone are the days of waiting for hours or even days for your 3D prints to complete. The latest 3D printers boast impressive speeds without compromising on accuracy. With advanced technologies, your designs can now be transformed into physical objects in a fraction of the time.

Multi-material and multi-color printing

Imagine being able to print objects in a variety of materials or even multiple colors. This is now a reality with the latest advancements in 3D printing. Whether you need flexible parts or want to add a touch of vibrancy to your creations, multi-material and multi-color printing options allow you to push the boundaries of what’s possible.

Larger scale printing

If you’re looking to bring your ideas to life on a grand scale, you’ll be pleased to know that larger scale 3D printing is now more accessible than ever. Whether you’re working on architectural models or life-sized prototypes, the latest printers can handle the challenge, providing you with the opportunity to create impressive, attention-grabbing designs.

Portable and compact printers

Do you want the freedom to unleash your creativity wherever you go? Portable and compact 3D printers are now available, allowing you to take your projects on the road. Whether you’re a designer, artist, or hobbyist, these portable printers offer convenience without sacrificing quality.

Innovation in 3D printing and additive manufacturing continues to redefine what’s possible. With a wide range of hardware advancements, you have the tools to bring your ideas into the physical world, revolutionizing the way we create and innovate. So, what are you waiting for? Let your imagination run wild with the endless possibilities of 3D printing.

This image is property of www.a2kstore.com.

## Software

In the rapidly evolving world of 3D printing and additive manufacturing, software advancements have taken center stage. Innovative developments in software have revolutionized the way 3D printers operate, offering users an enhanced level of control and efficiency. From advanced slicing software to the incorporation of artificial intelligence (AI) and machine learning, these cutting-edge software solutions are pushing the boundaries of what is possible in the realm of 3D printing.

Advanced slicing software

Gone are the days of manually configuring printer settings. Advanced slicing software now allows you to easily optimize your models for printing by automatically generating intricate layer-by-layer instructions. With features like customizable support structures, adaptive layer heights, and intelligent infill patterns, you can achieve unparalleled precision and quality in your prints.

Incorporation of AI and machine learning

The integration of AI and machine learning algorithms has paved the way for smarter 3D printers. These technologies enable printers to learn and adapt based on their environment, resulting in increased efficiency and reduced print failures. AI-powered systems can analyze complex geometries and optimize printing parameters, ensuring optimal performance and resource utilization.

Improved design and CAD software

Software tools for design and computer-aided design (CAD) have also experienced significant advancements. Intuitive interfaces, enhanced modeling capabilities, and improved mesh editing tools allow you to effortlessly create intricate designs. Moreover, cloud-based collaboration features enable seamless sharing and editing among teams, fostering innovation and creativity.

Simulation and optimization tools

Simulation and optimization tools have become invaluable assets for engineers and designers alike. These tools simulate the printing process, predicting potential issues and optimizing print parameters to achieve the desired outcome. By identifying problems before printing, resources and time can be saved, minimizing material waste and improving the overall efficiency of the printing process.

Remote monitoring and control

Thanks to remote monitoring and control software, you can now manage and monitor your 3D printer from anywhere in the world. Whether you are at home, in the office, or even on the go, you can easily connect to your printer and monitor the progress of your print. This technology allows for real-time adjustments and troubleshooting, ensuring a smooth printing experience and minimizing downtime.

As software continues to evolve, the possibilities for 3D printing and additive manufacturing are limitless. These advancements are making the printing process more efficient, reliable, and accessible, enabling individuals and industries to unlock the full potential of this groundbreaking technology. So, get ready to embrace the new era of 3D printing, where software innovation is driving the next wave of creative possibilities.

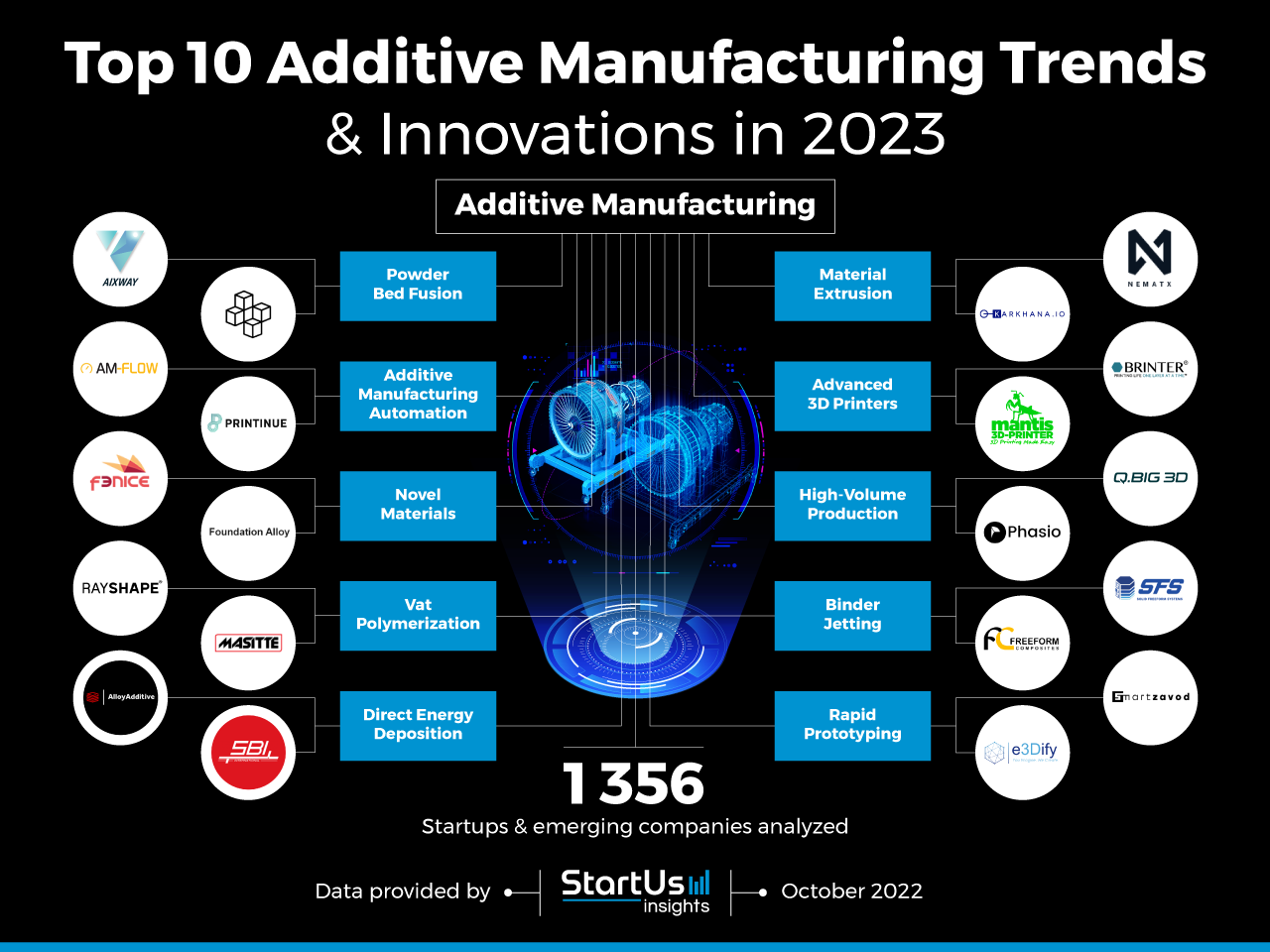

This image is property of www.startus-insights.com.

## Applications

With the rapid advancement of 3D printing technology and additive manufacturing, new applications are emerging across various industries. From revolutionizing medical procedures to transforming the way consumer products are designed and manufactured, the possibilities seem endless. Let’s explore some of the key areas where 3D printing is making waves.

Medical and healthcare industry

The medical field has witnessed groundbreaking 3D printed innovations, such as customized implants and prosthetics, which are tailored to individual patients’ needs. Furthermore, 3D printing has enabled the creation of complex anatomical models that help surgeons plan intricate procedures with greater precision.

Aerospace and defense

In the aerospace and defense sectors, 3D printing has paved the way for enhanced manufacturing processes, resulting in lighter and more efficient components. This technology enables the creation of intricate designs with superior strength and durability, contributing to improved aircraft performance and reduced weight.

Automotive industry

3D printing has revolutionized car manufacturing by providing the ability to rapidly prototype and produce complex components. This has led to the development of lighter and more fuel-efficient vehicles, as well as the customization of car interiors to meet individual preferences.

Consumer products

The consumer products industry has embraced 3D printing to create innovative and personalized items. From customized jewelry and fashion accessories to unique home decor, 3D printing allows for the production of one-of-a-kind products that resonate with consumers.

Architecture and construction

3D printing has also made its mark in the architecture and construction sectors by enabling the creation of intricate and intricate structures. This technology has the potential to revolutionize the way buildings are designed and constructed, offering more sustainable and cost-effective solutions.

The applications of 3D printing and additive manufacturing are diverse and continue to expand across various industries. As this technology continues to evolve, we can expect even more exciting innovations in the future. Whether it’s in the medical field, aerospace, automotive, consumer products, or architecture, 3D printing is transforming the way things are made and shaping the future of manufacturing.

This image is property of blog.orderfox.com.

## Processes

As 3D printing and additive manufacturing continue to evolve, new printing techniques are being introduced to expand the capabilities of this technology. These advancements are revolutionizing industries and opening up a world of possibilities.

Introduction to new printing techniques

Innovative printing techniques are constantly being developed, such as stereolithography (SLA) and digital light processing (DLP), which use light to cure liquid resin into solid objects. These techniques offer enhanced precision and faster printing speeds, allowing for the creation of intricate and complex designs.

Advancements in post-processing

Post-processing has also seen significant improvements, with new methods being developed to refine the surface finish and strength of printed objects. Techniques like vapor smoothing and electroplating are being used to achieve smooth and glossy finishes, while heat treatment and annealing are enhancing the strength and durability of printed parts.

Integration of 3D printing in traditional manufacturing

3D printing is increasingly being integrated into traditional manufacturing processes. This integration allows for the creation of customized and on-demand parts, reducing the need for complex supply chains and inventory management. By implementing additive manufacturing alongside traditional methods, companies can achieve greater efficiency and flexibility in their production processes.

Hybrid manufacturing approaches

Hybrid manufacturing approaches, which combine 3D printing with subtractive manufacturing techniques like milling, are gaining popularity. These methods offer the benefits of both additive and subtractive processes, enabling the production of highly complex geometries with improved accuracy and speed.

Cost-effective production methods

One of the most significant advancements in 3D printing is the development of cost-effective production methods. With the introduction of new materials and technologies, the overall cost of 3D printing has significantly decreased, making it more accessible to a wider range of industries and applications.

The field of 3D printing and additive manufacturing is constantly evolving, with new processes and techniques being introduced to enhance its capabilities. These innovations are revolutionizing industries, offering greater precision, flexibility, and cost-effectiveness in production processes. By staying updated with the latest advancements, you can capitalize on the benefits of 3D printing and unlock a world of possibilities for your business.

This image is property of idtxs3.imgix.net.

## Quality and Reliability

In the world of 3D printing and additive manufacturing, ensuring the quality and reliability of printed objects is of utmost importance. That’s why advancements and innovations in this field have focused on various aspects to improve the overall printing process.

Analysis of material properties

Understanding the properties of different materials used in 3D printing is crucial to achieve high-quality outputs. Extensive research and analysis have been conducted to identify the best materials for specific applications, ensuring durability, strength, and functionality.

Improved printing accuracy

To achieve precise and intricate details in printed objects, advancements have been made to enhance printing accuracy. Cutting-edge technologies, such as improved nozzle designs and advanced software algorithms, allow for higher levels of precision, resulting in more accurate and precise creations.

Certification and standardization procedures

Certifications and standardization procedures play a vital role in ensuring the reliability and consistency of 3D printed products. Industry standards have been established, addressing factors such as materials, printing processes, and final product quality. This ensures that printed objects meet the required standards and are reliable for various applications.

Maintenance and calibration best practices

Proper maintenance and calibration are crucial for consistent and reliable 3D printing. Innovations in this area focus on providing users with improved tools and procedures for maintaining and calibrating their printers. By following best practices, users can minimize errors and maintain high-quality printing performance.

Monitoring and quality control systems

Real-time monitoring and quality control systems have been developed to enhance the overall printing process. These systems allow for continuous monitoring of print parameters, detecting and addressing any potential issues during the printing process. By implementing such systems, users can minimize print failures and ensure the production of high-quality objects.

With a strong focus on quality and reliability, the latest 3D printing innovations and additive manufacturing advancements are revolutionizing the industry. By improving material analysis, printing accuracy, standardization procedures, maintenance practices, and implementing monitoring systems, the future of 3D printing looks promising.

Sustainability

Reducing waste and environmental impact

With the rapid advancements in 3D printing and additive manufacturing, sustainability has emerged as a key focus. Innovations in this field aim to minimize waste and reduce the overall environmental impact of the manufacturing process. One notable development is the ability to use recycled materials, such as plastic and metal, to create new printed objects. By repurposing waste, you can contribute to a more circular economy and reduce the reliance on virgin resources.

Recyclable and biodegradable materials

In addition to recycling, researchers and engineers have been exploring the use of recyclable and biodegradable materials in 3D printing. These materials, ranging from bioplastics to bio-based polymers, offer alternative options that are more sustainable and environmentally friendly. The ability to create objects that can safely decompose or be recycled at the end of their useful life helps to conserve resources and reduce pollution.

Energy-efficient printing processes

Energy efficiency is another area of focus in 3D printing innovations. By optimizing the printing processes and reducing energy consumption, manufacturers are able to minimize their carbon footprint. This includes advancements in printer design, software algorithms, and temperature control systems. These energy-efficient practices not only benefit the environment but also help businesses reduce their operating costs.

Circular economy and resource management

3D printing enables a more circular economy by allowing for localized production and customization. This means that products can be manufactured on-demand and closer to the point of use, minimizing transportation and distribution-related emissions. Additionally, 3D printing also facilitates resource management through the ability to reuse and repurpose materials, reducing the need for raw material extraction.

Life-cycle assessment of printed products

Understanding the environmental impact of printed products throughout their life cycle is crucial for sustainable manufacturing. Life-cycle assessment (LCA) techniques are being integrated into the design and production processes of printed objects. By analyzing factors such as material sourcing, production, use, and end-of-life disposal, LCA helps identify areas for improvement and inform sustainable design practices.

Sustainability is a key focus in 3D printing and additive manufacturing innovations. By reducing waste, utilizing recyclable and biodegradable materials, improving energy efficiency, embracing the circular economy, and conducting life-cycle assessments, the industry is making significant strides toward a more sustainable future.

Education and Training

With the rapid advancements in 3D printing and additive manufacturing technology, staying up to date is crucial. Fortunately, there are several exciting developments in education and training that can help you enhance your knowledge and skills in this field.

Integration of 3D printing in education

Educational institutions are increasingly embracing 3D printing as a valuable tool for student learning. From elementary schools to universities, educators are incorporating 3D printing into their curricula to foster creativity, critical thinking, and problem-solving skills. Students can now bring their designs to life, gaining a deeper understanding of concepts and promoting hands-on learning.

Training programs for users and designers

To fully leverage the potential of 3D printing, training programs are available for both users and designers. These programs provide comprehensive guidance on operating 3D printers, optimizing designs for additive manufacturing, and troubleshooting common issues. By participating in these programs, you can acquire the necessary skills to achieve high-quality prints and create innovative designs.

Access to online resources and tutorials

The internet has become a goldmine for 3D printing enthusiasts, offering access to a vast array of resources and tutorials. Online platforms provide step-by-step guides, video tutorials, and troubleshooting tips to help you navigate the world of 3D printing. Whether you are a beginner or an experienced user, these resources can assist you in mastering new techniques and exploring innovative applications.

Collaborative platforms for knowledge-sharing

The 3D printing community is known for its collaborative nature, and there are numerous platforms where enthusiasts can share knowledge, ideas, and designs. Online forums, social media groups, and maker spaces enable you to connect with like-minded individuals, seek advice, and collaborate on projects. By participating in these communities, you can stay informed about the latest trends, discover new techniques, and forge valuable connections with experts in the field.

Emerging opportunities in additive manufacturing careers

As the use of 3D printing and additive manufacturing continues to expand, so do the career opportunities in this field. From design engineers to technicians and manufacturing specialists, there is a growing demand for individuals with expertise in 3D printing. By staying updated on the latest innovations and training opportunities, you can position yourself for a rewarding career in additive manufacturing.

The advancements in 3D printing and additive manufacturing technology have opened up new avenues for education and training. Integration of 3D printing in education, specialized training programs, online resources and tutorials, collaborative platforms, and emerging career opportunities are just a few examples of how you can stay ahead in this exciting field. So, embrace the 3D printing revolution and embark on a journey of continuous learning and growth!

Business and Market Trends

Growth and adoption of 3D printing

The world of 3D printing and additive manufacturing is experiencing significant growth and adoption across industries. Companies are recognizing the potential of this technology to revolutionize their manufacturing processes, resulting in increased market demand. From aerospace to healthcare, 3D printing is becoming an integral part of production.

Emerging market players and startups

A notable trend in the industry is the emergence of new market players and startups. These innovative companies are pushing the boundaries of what is possible with 3D printing, introducing cutting-edge technologies and materials. Their fresh ideas and willingness to experiment are driving the industry forward at a rapid pace.

Customization and on-demand manufacturing

One of the key advantages of 3D printing is the ability to create highly customized products on-demand. This capability is being embraced by industries such as fashion, automotive, and consumer goods, where personalized products are in high demand. Customers now have the opportunity to participate in the design process, resulting in truly unique and tailored products.

Disruptive business models

3D printing has also enabled the development of disruptive business models. Traditional supply chains are being disrupted as companies can now manufacture products locally, reducing logistics costs and lead times. Additionally, the rise of additive manufacturing services allows businesses to outsource their production needs, providing flexibility and scalability.

Economics of additive manufacturing

The economics of additive manufacturing are constantly evolving. As technology improves and materials become more cost-effective, the economics of using 3D printing for production are becoming increasingly favorable. This shift is driving adoption across industries and allowing companies to realize cost savings and efficiencies in their manufacturing processes.

The world of 3D printing and additive manufacturing is experiencing a multitude of exciting trends. From the growth and adoption of the technology to the emergence of new market players and disruptive business models, the industry is undergoing a rapid transformation. With the ability to customize products, provide on-demand manufacturing, and improve economics, 3D printing is set to revolutionize the way we manufacture and consume goods.

Challenges and Future Outlook

With the rapid evolution of 3D printing and additive manufacturing technology, there are several challenges and considerations that need to be addressed.

Overcoming limitations in material properties

One of the key aspects of 3D printing is the range of materials that can be used. However, each material has its own limitations in terms of strength, flexibility, and durability. Researchers and engineers are constantly working towards developing new materials that can overcome these limitations and meet the specific requirements of different applications. This includes experimenting with new composites, improving material properties through additives, and optimizing printing parameters for better performance.

Regulatory considerations for specific applications

As the applications of 3D printing expand into areas such as healthcare and aerospace, regulatory considerations come into play. Ensuring quality control, safety, and compliance with industry standards is crucial. Government agencies and regulatory bodies are actively working with industry experts to establish guidelines and regulations for the use of 3D printing in specific applications, such as medical devices and aircraft parts.

Addressing intellectual property concerns

With the ease and accessibility of 3D printing, protecting intellectual property rights has become a concern. Companies and individuals need to be cautious about unauthorized replication or counterfeiting of their products. Developing effective strategies to safeguard intellectual property, such as encryption or watermarking techniques, is essential in the age of 3D printing.

Scaling up production and reducing costs

While 3D printing offers great potential for on-demand manufacturing and customization, there are still challenges in scaling up production and reducing costs. Improving printing speed, increasing the size of printable objects, and optimizing the efficiency of materials are areas of focus for researchers and manufacturers. As advancements are made in these areas, the cost-effectiveness of 3D printing will continue to improve, making it a more viable option for mass production.

Predictions for the future of 3D printing

The future of 3D printing holds exciting possibilities. With ongoing research and developments, we can expect to see advancements in areas such as bioprinting, nanotechnology, and multi-material printing. Bioprinting technology has the potential to revolutionize healthcare by enabling the creation of organs and tissues for transplantation. Nanotechnology integration could lead to the production of intricate and precise components with enhanced properties. Furthermore, multi-material printing could open up new design possibilities and expand the range of applications for 3D printing. As technology continues to evolve, it is certain that 3D printing will shape the future of manufacturing in various industries.